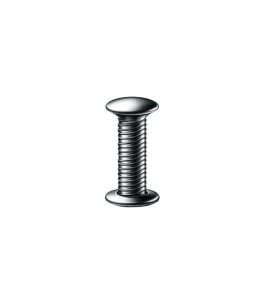

Solid Rivet

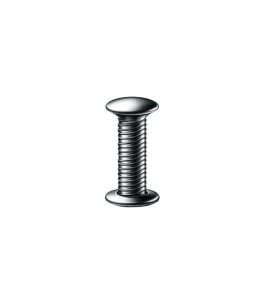

Solid Rivet

Solid Rivet

A solid rivet is a type of mechanical fastener consisting of a cylindrical shaft with a head on one end. It is one of the oldest and most reliable types of fasteners, used to join two or more pieces of material, typically metal.

Here are the key aspects of solid rivets:

1.Structure: A solid rivet typically has a straight shaft with a round or flat head on one end. The other end, known as the tail, is deformed during installation to form a second head, securing the materials in place.

2.Material: Solid rivets can be made from various materials, including steel, aluminum, copper, and brass, depending on the strength and corrosion resistance needed for the application.

3.Installation: To install a solid rivet, a hole is first drilled or punched through the materials to be joined. The rivet is then inserted, and the tail end is deformed using a hammer or a riveting tool (like a rivet gun or a pneumatic hammer). This process, known as “upsetting,” expands the tail to about 1.5 times its original diameter, clamping the materials together securely.

4.Uses: Solid rivets are used in applications where reliability and strength are critical, such as in structural steel construction, bridge building, aircraft manufacturing, and shipbuilding.

5.Advantages: They offer excellent strength and durability, making them ideal for heavy-load applications and structures exposed to high stress or vibrations. They also provide a smooth and clean appearance on the surface.

6.Limitations: The installation of solid rivets typically requires access to both sides of the assembled materials and can be labor-intensive, especially for large structures or where many rivets are needed.

Solid rivets are a proven, effective solution for permanently joining materials, especially in situations where strength and durability are paramount.