Sheet Metal Screw

Sheet Metal Screw

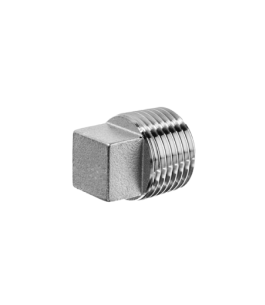

A sheet metal screw is a type of fastener, usually made of steel, used primarily for connecting thinner metal objects or sheet metal. These screws are characterized by their sharp threads and pointed end, which allow them to easily penetrate and grip into sheet metal and other thin materials. They come in various shapes and sizes, with different head types like flat head, pan head, or hex head, and they can have either a Phillips, flat, or other drive type.

The threads of a sheet metal screw are designed to be self-tapping, meaning they can create their own threads as they are driven into the material. This makes them particularly useful for materials that are too thin to be effectively pre-threaded, as in the case with thicker materials. Sheet metal screws are commonly used in HVAC, automotive, and general metal fabrication applications. They can be found in a range of materials, including stainless steel, for corrosion resistance, and in various coatings for additional durability or aesthetic purposes