Washers

USS Flat Washer

A USS flat washer, named after the United States Standard (USS) for washers, is a type of flat washer used to distribute the load of a threaded fastener, such as a bolt or nut. The USS designation refers to the dimension and thickness standards that these washers comply with, as set by the United States Standard. This ensures uniformity in size and shape across different manufacturers.

SAE Flat Washer

An SAE flat washer, named after the Society of Automotive Engineers, is a type of flat washer used to distribute the load of a threaded fastener like a screw or bolt. These washers are designed according to SAE standards, which specify their size and thickness.

Fender Washer

A fender washer is a type of flat washer known for its large outside diameter in relation to its central hole size. This design feature allows it to distribute loads over a wider surface area, making it ideal for use in thin materials or on soft surfaces where a standard washer might pull through.

Zip Washer

A zip washer, also known as a split washer or a split lock washer, is a type of washer designed to provide a spring force and create friction to prevent nuts and bolts from loosening. Zip washers are characterized by a ring shape that is split at one point and then twisted, creating a helical shape. This split and twist give the washer its spring-like property.

Ogee Washer

An O-G washer, also known as an offset washer or an off-center washer, is a specialized type of washer with a hole that is not in the center of the washer but offset to one side. The offset hole allows the washer to be used in situations where alignment or positioning is critical. When placed on a bolt or a shaft, the offset hole can be used to adjust the position of the washer, thereby altering the alignment of the assembly.

Square Washer

A square washer is a type of washer with a distinctive square outer shape and a central hole, typically round, designed to accommodate a bolt or screw. Square washers are a practical choice in applications where standard round washers may not provide sufficient surface area or where specific alignment needs are present. Their unique shape offers advantages in terms of stability and load distribution in various construction and assembly tasks.

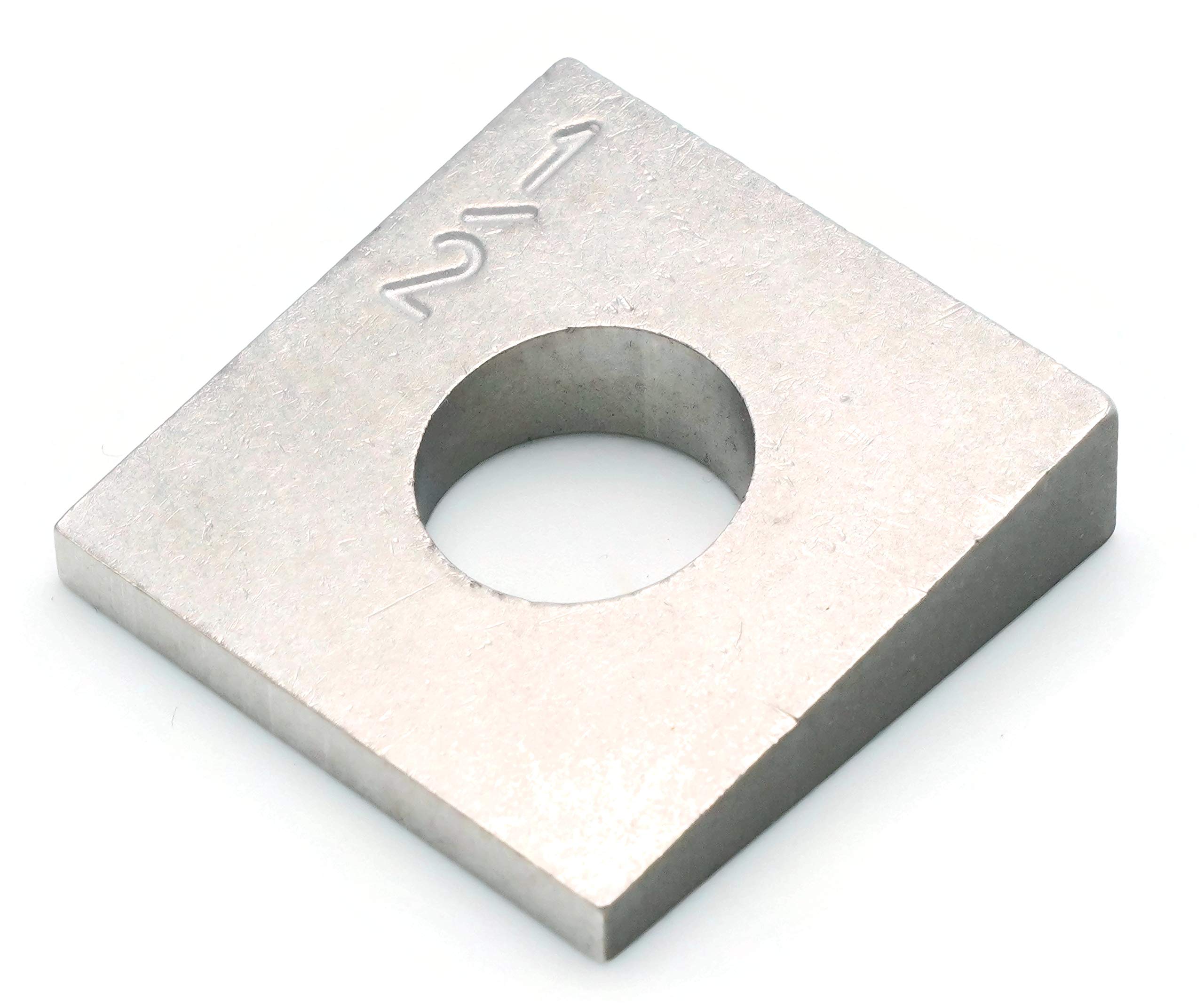

Bevel Washer

A beveled washer, also known as an angular washer, is a type of washer designed with a beveled or angled surface. The main function of a beveled washer is to accommodate surface irregularities or to be used in applications where a bolt needs to be seated at a particular angle. This is often required in situations where the surface being bolted is not perpendicular to the bolt axis.

Neopreme GasketWasher

A neoprene gasket washer is a specialized type of washer made from neoprene, a type of synthetic rubber known for its versatility and durability. It has excellent chemical stability and maintains flexibility over a wide temperature range. Besides acting as gaskets, these washers can also provide vibration dampening and cushioning in mechanical assemblies.

Cup (Finishing) Washer

A cup washer, also known as a finishing washer, is a specialized type of washer designed for aesthetic and functional purposes in fastening applications. Cup washers have a countersunk or cupped design, which means they are shaped like a shallow bowl with a hole in the center. This design allows them to hold the head of a countersunk screw, bolt, or similar fastener.

Load Indicating Washer

A load indicating washer (LIW) is a specialized type of washer designed to provide a visual or measurable indication of the tension within a bolted joint. This type of washer is instrumental in ensuring the proper load is applied to a bolted connection, which is crucial in various structural, mechanical, and engineering applications. Squirting style also available.

Split Ring Lockwasher

A regular lockwasher, also known as a split lock washer, is a type of fastener used to prevent bolts and nuts from loosening over time, especially under vibration or changing loads. When a bolt or nut is tightened over a regular lockwasher, the washer’s split ends are compressed. This compression creates a spring force and a gripping action. The tension generated by the washer’s spring-like action increases friction between the bolt and the washer, and between the washer and the mating surface, helping to prevent the bolt from loosening.

Internal Tooth Lockwasher

An internal tooth lockwasher is a type of washer designed to prevent a bolt or screw from loosening due to vibration or rotation. The most distinctive feature of a regular lockwasher is its helical or split design. It looks like a ring that has been cut and then twisted into a helical shape. This split in the washer allows it to act like a spring.

Belleville Washer

Belleville washers are used primarily to add pre-load to a nut and bolt assembly. They add a layer of force between the bolt head and the installation surface when placed under the head of the bolt. This serves as a resistance to vibration to prevent accidental loosening, which is why these washers are commonly found on automobiles, airplanes, and heavy machinery.

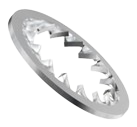

External Tooth Lockwasher

An external tooth lockwasher, also known as a star washer, is designed to prevent bolts and screws from loosening, typically due to vibration or rotation. External tooth lockwashers have teeth or serrations that extend outward from the outer circumference of the washer. These teeth are sharp and are designed to bite into the material surface and the bolt or screw head, creating a more secure hold.

High Collar Lockwasher

A high collar lockwasher is a specific type of lockwasher designed primarily for use with socket head cap screws. The high collar lockwasher has a split design similar to a standard split lock washer. However, it is distinguished by a higher profile or taller collar. This design is tailored to fit into the deeper countersink of socket head cap screws.

Disc Lockwasher

A disc lockwasher, commonly known as a Belleville washer or a conical spring washer, is a type of washer with a unique design used to apply a constant force within bolted joints, thereby preventing bolt loosening. The washer has a conical or disc-like shape. This design allows the washer to flex, providing a spring-like action. When the bolt is tightened, the washer is compressed, which stores potential energy and creates a spring force.

Combination (Int./Ext.) Lockwasher

A combination internal and external tooth lockwasher is a specialized type of washer that merges the features of both internal and external tooth lockwashers. This design enhances the washer’s ability to prevent loosening of fasteners, particularly in applications involving vibration and rotation. The inward-facing teeth grip the head of the bolt or screw, while the outward-facing teeth bite into the mounting surface. This dual grip ensures a more secure hold, effectively resisting loosening due to vibration or rotational forces.